From impulse turbines to reaction turbines, each design serves a specific purpose in harnessing energy from steam. However, it’s essential to ensure the optimal performance and longevity of these turbines. This brings us to the significance of turbine oil purification. By maintaining oil cleanliness and its quality, turbine efficiency can be maximized, reducing wear and tear, and extending the lifespan of these remarkable machines. Now, let’s delve into a comprehensive guide exploring the different Types of steam turbines, their applications, and the factors to consider when selecting the most suitable one for your needs.

Table of Contents

Understanding Steam Turbines

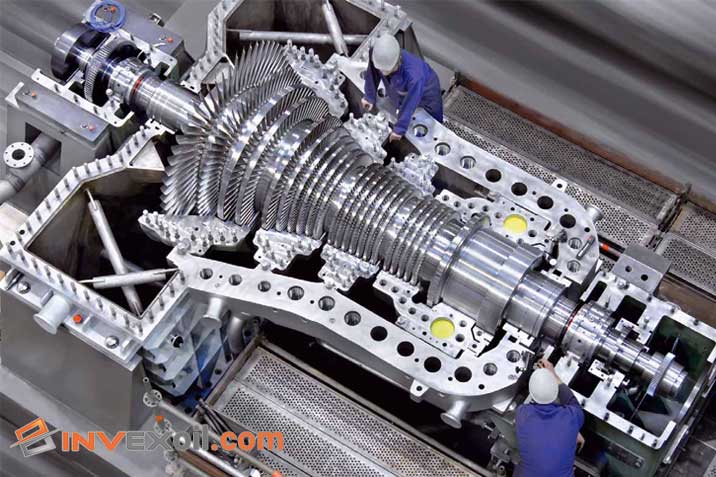

Steam turbines are remarkable machines that convert the energy of high-pressure steam into mechanical energy. They play a crucial role in various industries, from power generation to manufacturing processes.

What Is a Steam Turbine?

A steam turbine is a rotary device that utilizes the expansive force of steam to produce rotational motion. As high-pressure steam passes through the turbine blades, it imparts energy, causing the turbine to rotate. This rotational motion is then harnessed to drive generators, pumps, or other mechanical equipment.

How Do Steam Turbines Work?

Steam turbines work on the principle of the Rankine cycle. The cycle involves four main stages: steam generation, expansion, condensation, and compression. In the expansion stage, the high-pressure steam expands through the turbine, extracting energy and converting it into rotational motion. The condensed steam is then recycled, completing the cycle.

Importance Types of steam turbines

Steam turbines hold immense importance in the realm of power generation and industrial processes. Their versatility, efficiency, and reliability make them indispensable in various applications.

Applications Types of steam turbines

Steam turbines find wide-ranging applications across different industries. Some notable applications include:

- Power Generation: Steam turbines play a vital role in generating electricity in thermal power plants. They convert the thermal energy from burning fossil fuels or nuclear reactions into mechanical energy and then into electrical energy.

- Marine Propulsion: Steam turbines power ships and vessels, providing efficient propulsion for naval and commercial purposes.

- Oil and Gas: Steam turbines are used in the oil and gas industry for driving pumps, compressors, and generators, aiding in extraction, refining, and distribution processes.

- Industrial Processes: Industries such as chemical, paper, and sugar rely on steam turbines to drive various machinery and equipment.

Advantages Types of steam turbines

The advantages Types of steam turbines include:

- High Efficiency: Steam turbines offer excellent efficiency in converting thermal energy into mechanical energy, ensuring maximum utilization of fuel.

- Scalability: Steam turbines can be designed for a wide range of power outputs, making them suitable for both large-scale power plants and small-scale industrial applications.

- Reliability: Steam turbines are known for their robustness and reliability, with long operational lifespans and minimal maintenance requirements.

Classification Types of steam turbines

Steam turbines can be classified into different types based on their operating principles and design characteristics. Understanding the classification helps in determining the most suitable turbine for specific applications.

Impulse Turbines

Impulse turbines are Types of steam turbine that operates based on the principle of impulse and reaction. In impulse turbines, high-pressure steam passes through nozzles, creating a high-velocity jet that impacts the turbine blades. This impulse causes the blades to rotate, converting the steam’s kinetic energy into mechanical energy.

Single-Stage Impulse Turbine

A single-stage impulse turbine consists of a single set of nozzles and rotor blades. It is primarily used for small-scale power generation and industrial applications. The simplicity of design and compactness make it suitable for situations where space is limited.

Multi-Stage Impulse Turbine

A multi-stage impulse turbine consists of multiple stages, each having a set of nozzles and rotor blades. The expansion of steam occurs in several stages, resulting in increased efficiency and improved performance. Multi-stage impulse turbines are commonly used in large-scale power plants to generate electricity.

The table provides a comparison between single-stage and multi-stage impulse turbines, highlighting key parameters and their differences.

| Parameter | Single-Stage Impulse Turbine | Multi-Stage Impulse Turbine |

| Efficiency | Moderate | High |

| Power Output | Low | High |

| Size and Footprint | Compact | Larger |

| Suitable Applications | Small-scale power generation | Large-scale power plants |

Reaction Turbines

Reaction turbines are another Types of steam turbine commonly used in various industrial applications and power generation. Unlike impulse turbines, reaction turbines operate on the principle of both impulse and reaction forces, making them highly efficient and suitable for large-scale power plants.

Single-Stage Reaction Turbine

A single-stage reaction turbine consists of a single set of fixed and moving blades. As the steam passes through the blades, it expands and reacts with the moving blades, causing them to rotate. These turbines are typically used in applications where moderate power output is required.

Multi-Stage Reaction Turbine

A multi-stage reaction turbine consists of multiple stages, each containing a series of fixed and moving blades. The expansion of steam occurs gradually across these stages, resulting in increased efficiency and higher power output. Multi-stage reaction turbines are commonly employed in large power plants for electricity generation.

The table provides a comparison between single-stage and multi-stage reaction turbines, highlighting key parameters and their differences.

| Parameter | Single-Stage Reaction Turbine | Multi-Stage Reaction Turbine |

| Efficiency | Moderate | High |

| Power Output | Moderate | High |

| Size and Footprint | Compact | Larger |

| Suitable Applications | Moderate power generation | Large-scale power plants |

6 Common Types of steam turbines

Steam turbines are widely used in various industries for power generation and mechanical drive applications. Understanding the different Types of steam turbines is essential for selecting the most suitable option for specific requirements.

Condensing Turbine

A condensing turbine is a type of steam turbines that operates with a high-pressure steam inlet and utilizes a condenser to convert the exhaust steam into water. This allows for improved efficiency by recovering the latent heat of vaporization. Condensing turbines are commonly used in power plants and large-scale industrial processes.

The table provides a comparison of different types of condensing turbines, highlighting key parameters and their distinctions.

| Parameter | Condensing Turbine | Backpressure Turbine | Extraction Condensing Turbine |

| Steam Inlet Pressure | High | High | High |

| Steam Outlet Pressure | Sub-atmospheric | Above Atmospheric | Sub-atmospheric |

| Power Generation | Yes | Yes | Yes |

| Process Steam Output | No | Yes | Yes |

| Applications | Power plants, industries | Cogeneration, refineries | Pulp and paper, industries |

Backpressure Turbine

A backpressure turbine is designed to generate both power and process steam. Unlike a condensing turbine, it releases exhaust steam at a pressure above atmospheric. This makes it suitable for applications where both electricity and steam are required, such as cogeneration systems in industries like refineries and chemical plants.

Extraction Condensing Turbine

An extraction condensing turbine combines the features of a condensing turbine and an extraction turbine. It allows for the extraction of steam at various stages for process heating or other industrial purposes, while the remaining steam is condensed in a condenser. This type of turbine finds applications in industries where both power and process steam demands exist, such as pulp and paper manufacturing.

Non-Condensing Turbine

Non-condensing turbines are a type of steam turbines that operates without a condenser to convert the exhaust steam back into water. These turbines are commonly used in applications where the exhaust steam is not required for further use or recovery. Non-condensing turbines are known for their simplicity and cost-effectiveness.

The table provides a comparison of different types of non-condensing turbines, highlighting key parameters and their distinctions and know more about Types of steam turbine.

| Parameter | Backpressure Non-Condensing Turbine | Extraction Non-Condensing Turbine |

| Steam Inlet Pressure | High | High |

| Steam Outlet Pressure | Above Atmospheric | Above Atmospheric |

| Power Generation | Yes | Yes |

| Extraction Steam Output | No | Yes |

| Applications | Power generation | Industrial processes |

Backpressure Non-Condensing Turbine

A backpressure non-condensing turbine is designed to generate power while releasing the exhaust steam at a pressure above atmospheric. This type of turbine is commonly utilized in situations where power generation is the primary objective and there is no need for extracting or utilizing the exhaust steam.

Extraction Non-Condensing Turbine

Extraction non-condensing turbines allow for the extraction of steam at various stages for industrial processes or heating purposes. These turbines are used in applications where both power generation and process steam demands exist, and the exhaust steam is not required to be converted back into water.

Conclusion

This article has explored the various types of steam turbines and their key features, including reheat turbines, geared turbines, industrial turbines, and small-scale turbines. We discussed the factors to consider when choosing a steam turbine, such as power output requirements, steam conditions, and efficiency. Additionally, we delved into advanced technologies like supercritical and ultra-supercritical steam turbines, advanced materials and coatings, and digital monitoring systems.

Understanding the diverse options available in steam turbine technology empowers decision-makers to make informed choices for their specific needs, whether it’s achieving higher efficiency, reducing emissions, or optimizing power output. By embracing these advancements, industries can harness the full potential Types of steam turbines and contribute to a sustainable energy future.

FAQ

These questions are the most commonly asked ones regarding this topic about Types of steam turbine:

What are the different Types of steam turbines?

The main Types of steam turbines include condensing turbines, backpressure turbines, and extraction condensing turbines.

What is a condensing turbine?

A condensing turbine is a type of steam turbines that exhausts steam in a partially condensed state, maximizing energy extraction.

What is a backpressure turbine?

A backpressure turbine is a steam turbine that exhausts steam at a pressure above atmospheric, typically used for cogeneration or industrial processes.

Hello, This is Matteo Hudson Copywriter from InvexOil. We are here to provide super-important content to help you learn more easily and be involved in the world of Petroleum and Chemistry. We are here to answer your questions, help you to have better services, and also find the best solution for your problems. Don’t be shy and ask your questions in the comment box or call our number. If you want to connect with me directly, you can search for my name on Linkedin.