These days, airplanes play the most important role in the transportation industry. it generates economic growth, creates jobs, and facilitates international trade and tourism. the most important part of aviation experience is the turbine engine because it makes the airplane flow in the air but how does a turbine engine work? In this article, we will explore turbine engines’ working principles and the significance of turbine oil regeneration in maintaining their reliability, performance, and longevity.

Table of Contents

What is a Turbine Engine?

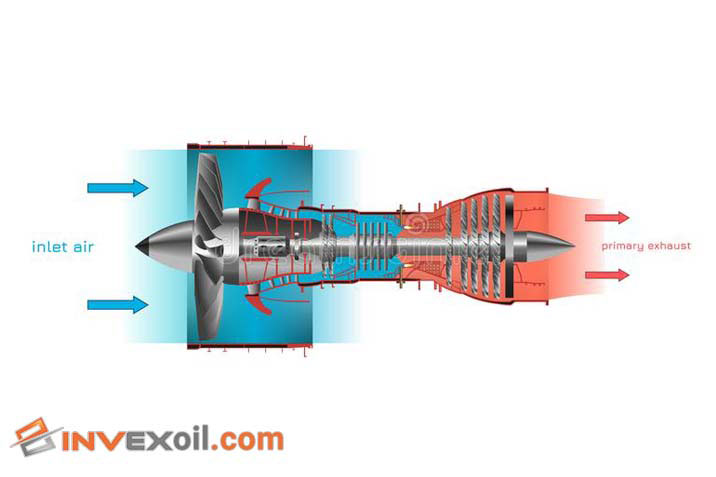

A turbine engine is a type of internal combustion engine that converts the energy of flowing gases into mechanical energy, resulting in propulsion or generating power. It operates on the principle of extracting energy from the continuous flow of exhaust gases, which drives a series of rotating components. These engines are commonly used in aircraft, power generation plants, and various industrial applications due to their high efficiency and power output.

Basic Principles of a Turbine Engine

A turbine engine operates on the fundamental principles of energy conversion and propulsion. It is an internal combustion engine that converts the energy of flowing gases into mechanical energy, which is used to generate thrust or power. By harnessing the energy from the continuous flow of exhaust gases, turbine engines provide efficient propulsion for aircraft, power generation, and industrial applications.

Energy Conversion in a Turbine Engine!

Energy conversion in a turbine engine involves several stages. The process begins with the intake of ambient air, which is compressed in the engine’s compressor section. The compressed air then enters the combustion chamber, where it combines with fuel and undergoes combustion, releasing a tremendous amount of heat and energy. This high-pressure and high-temperature gas expands rapidly through the turbine, causing the turbine blades to rotate. The rotating turbine powers both the compressor and the engine’s output, such as the fan in aircraft engines or the generator in power plants.

The Role of Air in a Turbine Engine

Air plays a crucial role in a turbine engine’s operation. For find out how does a turbine engine work, we have to know the role of air in a turbin Engine. During the intake phase, large quantities of ambient air are drawn into the engine. This air is essential for the combustion process, as it supplies oxygen to support fuel combustion. The compressor section compresses the air, increasing its pressure and preparing it for combustion. The compressed air is then mixed with fuel in the combustion chamber, where combustion occurs, releasing energy and propelling the engine.

And this is a table about Energy Conversion Efficiency Comparison.

| Energy Conversion Method | Efficiency (%) |

| Turbine Engine | 40-50 |

| Internal Combustion Engine | 20-40 |

| Electric Motor | 90-95 |

| Fuel Cell | 40-60 |

Components of a Turbine Engine

A turbine engine consists of several key components that work together to achieve energy conversion and propulsion. To know better how does a turbine engine work, we have to know them. These components include the compressor, combustion chamber, turbine, and exhaust nozzle. The compressor compresses the incoming air, increasing its pressure and density. The combustion chamber mixes the compressed air with fuel and ignites it, generating hot exhaust gases. The expanding exhaust gases flow through the turbine, driving its rotation. Finally, the exhaust nozzle releases the exhaust gases at high velocity, creating thrust or driving a power generator.

Table of Key Components of a Turbine Engine

| Component | Description |

| Compressor | Increases air pressure and density before entering the combustion chamber. |

| Combustion Chamber | Mixes compressed air with fuel and ignites it, generating hot exhaust gases. |

| Turbine | Harnesses the energy from expanding exhaust gases to drive the rotation of the engine’s components. |

| Exhaust Nozzle | Releases exhaust gases at high velocity, creating thrust or driving a power generator. |

Importance of Understanding How does a turbine engine work

Understanding how does a turbine engine work is crucial for multiple reasons. Firstly, it enables engineers and technicians to effectively maintain and troubleshoot engine performance. Secondly, comprehension of turbine engine operation aids in identifying areas for optimization, leading to improved fuel efficiency and reduced emissions. Moreover, a deeper understanding allows for better design and innovation in turbine engine technology, driving advancements in aviation, power generation, and other industries.

Working Process of turbine engine work

A turbine engine follows a precise working process consisting of various phases that contribute to its efficient operation and power generation.

Inlet Phase

During the inlet phase, ambient air is drawn into the engine through the inlet duct or intake system. The inlet duct’s design ensures a smooth and uninterrupted airflow, minimizing air resistance and pressure losses. The incoming air passes through filters to remove any contaminants before entering the engine’s core components.

During the inlet phase, the engine draws in a significant amount of air to facilitate the combustion process. This phase is crucial for ensuring a consistent and uninterrupted supply of air. The inlet guide vanes play a vital role in controlling the airflow, directing it towards the compressor. By adjusting the angle of the vanes, the engine can optimize the air intake for efficient combustion.

The Role of the Inlet Guide Vanes

The inlet guide vanes are responsible for managing the air entering the engine. By adjusting their position, the vanes regulate the airflow velocity and direction, optimizing it for the compressor’s efficiency. This control mechanism helps maintain a steady air supply, preventing issues like compressor stalls and ensuring the engine operates within its designed parameters.

The Function of the Compressor

The compressor, an essential component of the turbine engine, is responsible for increasing the air pressure and density before it enters the combustion chamber. It achieves this by utilizing multiple stages consisting of rotating blades (rotor) and stationary blades (stator). To know better about how does a turbine engine work, As the air passes through the compressor, it undergoes compression, resulting in higher pressure and temperature. This compressed air is then ready for the combustion phase, where it interacts with fuel to generate power.

Compression Phase

In the compression phase, the incoming air is compressed to a higher pressure and temperature by the engine’s compressor. The compression is one of them most important parts of answering how does a turbine engine work. The compressor consists of multiple stages, each consisting of a row of rotating blades (rotor) and a stationary set of blades (stator). As the air passes through these stages, its pressure and density increase, preparing it for the next phase.

Compression Phase, Squeezing the Air

During the compression phase, the turbine engine compresses the air drawn in during the inlet phase, increasing its pressure and density. This crucial step sets the stage for efficient combustion and power generation. The compressor, a key component, plays a pivotal role in this phase.

How Does a Compressor Work?

The compressor utilizes a combination of rotating and stationary blades to compress the incoming air. As the rotor blades rotate, they accelerate the air, while the stator blades help redirect the airflow and further increase its pressure. This continuous squeezing action enables the compressor to significantly raise the air pressure, preparing it for combustion.

Types of Compressors Used in Turbine Engines

Turbine engines employ different types of compressors, each with its advantages and applications. Common compressor types include axial compressors, centrifugal compressors, and mixed-flow compressors. Axial compressors are highly efficient and widely used in aviation applications. Centrifugal compressors, on the other hand, excel at handling large volumes of air. Mixed-flow compressors combine characteristics of both axial and centrifugal compressors, offering a balance between efficiency and airflow capacity.

This table contain types of Compressors with Pros and Cons.

| Compressor Type | Pros | Cons |

| Axial Compressor | High efficiency | Limited volume handling |

| Centrifugal | High airflow capacity | Lower efficiency at high speeds |

| Mixed-flow | Balanced efficiency and volume | Complex design |

Combustion Phase, Igniting the Fuel!

In the combustion phase, fuel is injected into the compressed air in the combustion chamber. The mixture of fuel and air is ignited, resulting in a rapid and controlled combustion process. This combustion releases a significant amount of energy in the form of hot exhaust gases, creating a high-pressure and high-temperature gas stream.

Fuel Injection in a Turbine Engine

Fuel injection is the process of introducing fuel into the combustion chamber of a turbine engine. It is carefully timed and controlled to ensure efficient combustion and maximum power output. The fuel is atomized into small droplets and mixed with the compressed air, creating a combustible mixture that ignites to produce the desired power.

The Combustion Chamber and Its Role

The combustion chamber is a vital component where the fuel-air mixture is ignited and combustion takes place. It is designed to confine and control the combustion process, allowing it to occur within a specific area. The combustion chamber’s shape, size, and materials are optimized to enhance efficiency, promote complete combustion, and minimize emissions.

Expansion Phase, Harnessing the Power!

The expansion phase involves the utilization of the energy stored in the hot exhaust gases. The expanding gases flow through the turbine section, where they interact with the turbine blades. This interaction causes the turbine blades to rotate, harnessing the energy of the exhaust gases and converting it into mechanical energy. The rotation of the turbine is used to drive the compressor and other accessories attached to the engine.

During the expansion phase of a turbine engine, the hot, high-pressure gases produced during combustion expand rapidly. This expansion drives the turbine, which extracts energy from the gas flow and converts it into mechanical energy. The expanding gases pass through the turbine blades, causing them to rotate at high speeds.

The Turbine’s Role in the Expansion Phase

The turbine plays a crucial role in the expansion phase by converting the energy of the expanding gases into mechanical energy. As the hot gases flow through the turbine, they exert a force on the turbine blades, causing them to rotate. This rotational motion is used to power the compressor, as well as any other engine accessories or external machinery.

Exhaust Phase of how does a turbine engine work

In the exhaust phase, the exhaust gases exit the engine through the exhaust nozzle. The exhaust nozzle is designed to accelerate the gases, creating a jet-like exhaust stream. This high-velocity exhaust stream generates thrust in aircraft engines, propelling the aircraft forward. In other applications, such as power generation, the exhaust gases may be utilized further for other processes or released into the atmosphere.

Types of Turbines to know how does a turbine engine work

There are different types of turbines used in turbine engines, each with its own design and operational characteristics. Common types include axial flow turbines, radial flow turbines, and mixed flow turbines. These turbines are specifically engineered to optimize efficiency, power output, and compatibility with the engine’s operating conditions.

Types of Turbines and Their Applications are collected in this table to use them easily.

| Turbine Type | Application |

| Axial Flow | Large-scale aircraft engines |

| Radial Flow | Small aircraft engines, power generators |

| Mixed Flow | Industrial turbines, marine propulsion |

Exhaust Phase: Discharging the Exhaust Gases

In the exhaust phase of a turbine engine, the spent and cooled gases from the combustion process are expelled from the engine. These exhaust gases carry away the energy that was extracted by the turbine, releasing it into the atmosphere. The exhaust phase completes one full cycle of the turbine engine’s operation.

Exhaust Nozzles and Their Importance

Exhaust nozzles play a crucial role in the turbine engine’s performance. They are designed to control the flow and direction of the exhaust gases, optimizing thrust and efficiency. By carefully shaping the nozzle, the exhaust gases are accelerated, creating a higher velocity and generating more thrust. The design of the exhaust nozzle can have a significant impact on the engine’s overall performance and fuel efficiency.

how does a turbine engine work : Efficiency and Performance

Turbine engines are known for their impressive efficiency and performance. Their power-to-weight ratio, which measures the engine’s power output relative to its weight, is one of the key factors contributing to their effectiveness. Turbine engines have a high power-to-weight ratio, allowing them to generate significant thrust with relatively low weight.

Power-to-Weight Ratio

The power-to-weight ratio of a turbine engine determines its ability to produce power efficiently. It is calculated by dividing the engine’s power output by its weight. Higher power-to-weight ratios indicate better performance, as the engine can generate more power with less weight.

Specific Fuel Consumption

Specific fuel consumption is another important measure of turbine engine performance. It quantifies the amount of fuel required to generate a unit of power over a specific period. Lower specific fuel consumption values indicate higher fuel efficiency, meaning the engine can produce more power using less fuel.

Thrust and Propulsion

Thrust is the force that propels an aircraft forward and is a critical aspect of turbine engine performance. To know better this performance, we have to know better about how does a turbine engine work. By expelling exhaust gases at high speeds, turbine engines generate thrust to overcome drag and propel the aircraft. The design of the engine, including the exhaust nozzle, influences the magnitude of thrust produced.

Types of Turbine Engines

Turbine engines are versatile power plants used in various applications. They can be categorized into three main types: turbojet engines, turboprop engines, and turbofan engines.

Turbojet Engines

Turbojet engines are the earliest and simplest form of turbine engines. They generate thrust by compressing and combusting air with fuel in the combustion chamber. The hot exhaust gases are then expelled through the nozzle, creating forward propulsion. Turbojet engines are commonly used in high-speed military aircraft and some business jets.

Turboprop Engines

Turboprop engines combine the principles of a turbine engine and a propeller. They generate thrust by using a turbine to drive a propeller. Turboprops are highly efficient at lower speeds and are commonly used in regional airliners and small aircraft. They provide good fuel efficiency and excellent short takeoff and landing capabilities.

how does a turbine engine work in Turbofan Engines

Turbofan engines are the most common type of turbine engines used in commercial aviation. They consist of a core engine similar to a turbojet, but with an additional fan at the front. The fan bypasses a significant amount of air around the core, providing additional thrust and improved fuel efficiency. Turbofan engines are quieter and offer higher thrust-to-weight ratios, making them ideal for large passenger aircraft.

Conclusion

In this article we explored the fascinating world of turbine engines and knowing about how does a turbine engine work. We began by understanding the basic principles of turbine engines and their efficiency in converting fuel into propulsion. We delved into the compression phase, where air is squeezed to increase pressure, followed by the crucial combustion phase, where fuel is ignited for power generation.

We also examined the expansion phase, where the turbine harnesses the generated power, and the exhaust phase, where the discharge of exhaust gases occurs. Furthermore, we discussed different types of turbines and their applications, including turbojet, turboprop, and turbofan engines. Overall, understanding how turbine engines work is essential for appreciating their role in various industries, such as aviation, power generation, and more.

| Types of Turbine Engines | Description |

| Turbojet Engines | Earliest and simplest form of turbine engines. Used in high-speed military aircraft and some business jets. |

| Turboprop Engines | Combine turbine engine and propeller principles. Used in regional airliners and small aircraft for good fuel efficiency and short takeoff/landing capabilities. |

| Turbofan Engines | Commonly used in commercial aviation. Feature a core engine similar to a turbojet, with an additional fan at the front. Provide higher fuel efficiency, lower noise levels, and higher thrust-to-weight ratios. Ideal for large passenger aircraft. |

FAQ

What is the main principle behind the operation of a turbine engine?

A turbine engine operates on the principle of converting the energy from fuel combustion into mechanical energy to produce thrust.

How does a turbine engine generate power?

A turbine engine generates power by compressing incoming air, adding fuel for combustion, and then harnessing the energy from the expanding gases to drive the turbine.

What are the different types of turbine engines?

The main types of turbine engines include turbojet engines, turboprop engines, and turbofan engines, each designed for specific applications and performance requirements.

Hello, This is Matteo Hudson Copywriter from InvexOil. We are here to provide super-important content to help you learn more easily and be involved in the world of Petroleum and Chemistry. We are here to answer your questions, help you to have better services, and also find the best solution for your problems. Don’t be shy and ask your questions in the comment box or call our number. If you want to connect with me directly, you can search for my name on Linkedin.