As part of the process of how to make biodiesel from used cooking oil, it is important to properly recycle and filter the used oil. This used oil recycling process involves removing any impurities or contaminants, such as food particles or water, from the oil. Once the oil has been properly filtered, it can be used as a feedstock for the transesterification reaction that converts it into biodiesel. Proper Cooking oil into diesel conversion is essential to ensure that the resulting biodiesel meets the necessary quality standards and is compatible with diesel engines.

Table of Contents

What is Biodiesel?

For answer how to make biodiesel from used cooking oil and what is Biodiesel, we must tell you Biodiesel is a type of alternative fuel that is derived from renewable feedstocks, such as vegetable oils or animal fats, through a chemical process called transesterification. This process breaks down the feedstock into methyl esters, which can be used as a diesel substitute.

Biodiesel is typically blended with petroleum diesel fuel in different ratios, such as B5, which contains 5% biodiesel and 95% petroleum diesel, or B20, which contains 20% biodiesel and 80% petroleum diesel. In 2021, the global biodiesel market size was valued at $46.7 billion and is expected to grow at a CAGR of 5.2% from 2022 to 2028.

Step-by-Step to Cooking Oil into Diesel conversion

After reading information about how to make biodiesel from used cooking oil. In fact Making biodiesel from used cooking oil can be a rewarding and sustainable project. However, it is important to take safety precautions and follow a step-by-step guide to ensure a successful outcome.

Step 1: Safety Precautions

Before starting the biodiesel production process, it is important to take safety precautions. This includes wearing protective clothing and eyewear, working in a well-ventilated area, and following proper handling and storage procedures for the chemicals used in the process.

Step 2: Preparing the Chemicals

The first step in making biodiesel is preparing the chemicals. This includes measuring out the correct amounts of used cooking oil, methanol or ethanol, and catalyst, and ensuring that the reactor vessel and mixing equipment are clean and dry. The amount of methanol needed for the reaction is typically 20% of the total volume of oil.

| Catalyst Type | Advantages | Disadvantages |

| Sodium Hydroxide | Low cost, high reactivity | Corrosive, requires thorough washing to remove impurities |

| Potassium Hydroxide | High reactivity, produces less soap | Corrosive, requires thorough washing to remove impurities |

| Calcium Hydroxide | Non-corrosive, mild reaction conditions | Lower reactivity, longer reaction times |

| Sodium Methoxide | High reactivity, produces less soap | Corrosive, requires careful handling and storage |

| Potassium Methoxide | High reactivity, produces less soap | Corrosive, requires careful handling and storage |

| Homogeneous Acid | Can use lower quality oil, less washing required | Requires special equipment, slower reaction times |

| Heterogeneous Acid | Can use lower quality oil, easier to handle | Lower reactivity, requires special equipment |

Step 3: Mixing the Chemicals

The next step is to mix the chemicals together in the reactor vessel. This involves adding the catalyst to the methanol or ethanol, and then slowly pouring the mixture into the used cooking oil while stirring constantly. The mixture is then heated and stirred for a specific amount of time to allow the transesterification reaction to occur. Once the reaction is complete, the mixture is allowed to settle, and the biodiesel is separated from the glycerin through a washing process.

By following a step-by-step guide and taking safety precautions, it is possible to successfully produce high-quality biodiesel from used cooking oil. The reaction time for mixing the chemicals is typically 1-2 hours. Against questions, we have answer of how to make biodiesel from used cooking oil and we know the chemical process of that and how it was created.

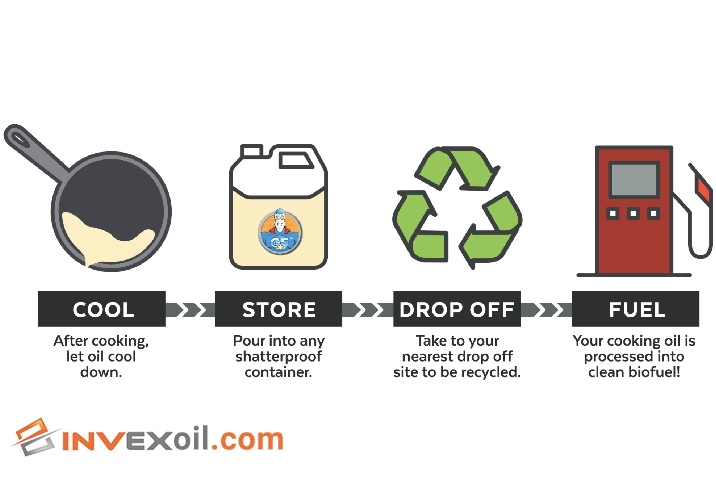

Collecting and Preparing Used Cooking Oil

Collecting and preparing used cooking oil is an important first step in the process of how to make biodiesel from used cooking oil. This involves identifying a source of used cooking oil and then properly filtering and preparing the oil for use as a feedstock for biodiesel production.

Where to Collect Used Cooking Oil

Used cooking oil can be collected from a variety of sources, including restaurants, cafes, and homes. Many businesses and households are willing to donate their used cooking oil for biodiesel production, as it helps to reduce waste and support a more sustainable economy. However, it is important to ensure that the used cooking oil is free of contaminants, such as food particles or water, which can interfere with the biodiesel production process.

Filtering the Used Cooking Oil

Once the used cooking oil has been collected, it must be properly filtered to remove any impurities or contaminants. This can be done through a variety of methods, such as using a filter press or a gravity filter. Proper filtering helps to ensure that the resulting biodiesel meets the necessary quality standards and is compatible with diesel engines.

It also helps to prolong the lifespan of the biodiesel production equipment and reduce maintenance costs. In fact Proper filtration of used cooking oil can remove up to 99% of impurities.

| Filter Type | Advantages | Disadvantages |

| Filter press | Effective at removing impurities and contaminants | Requires frequent maintenance and replacement |

| Gravity filter | Simple and cost-effective | May not remove all impurities and contaminants |

| Centrifuge | Fast and efficient | Can be expensive and requires skilled operation |

| Bag filter | Easy to use and replace | May not remove all impurities and contaminants |

| Cartridge filter | Effective at removing small particles and impurities | Requires frequent replacement |

This table is not exhaustive and there may be other types of filters available for filtering used cooking oil. The most suitable filter type will depend on the specific needs and requirements of the biodiesel production process. By know this information, you can answer how to make biodiesel from used cooking oil, question.

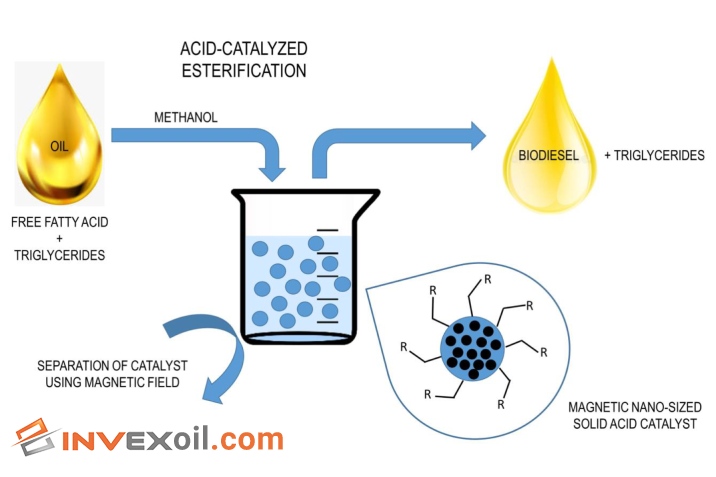

Chemical Process for Making Biodiesel

The chemical process for making biodiesel from used cooking oil involves a chemical reaction called transesterification. This process converts the oil into a form that is compatible with diesel engines, and requires the use of specific chemicals and equipment.

Transesterification Reaction

The transesterification reaction involves combining the used cooking oil with an alcohol, typically methanol or ethanol, in the presence of a catalyst, such as sodium hydroxide or potassium hydroxide. The reaction results in the formation of biodiesel and glycerin, which can be separated through a process called washing. After that, how to make biodiesel from used cooking oil can’t be important.

Required Chemicals and Equipment

To carry out the transesterification reaction and achieve, several chemicals and equipment are required. The chemicals include methanol or ethanol, a catalyst such as sodium hydroxide or potassium hydroxide, and a washing solution such as water or an acid. The equipment required includes a reactor vessel, a heating source, and a means of mixing the chemicals.

It is important to use high-quality chemicals and equipment to ensure the production of high-quality biodiesel that meets the necessary standards. The most common catalyst used in the transesterification reaction is sodium hydroxide (NaOH), which is typically used in a concentration of 0.5-1.0% of the total volume of oil

Advantages of Using Biodiesel

There are several advantages to using biodiesel, including its lower emissions and higher biodegradability compared to traditional diesel fuel. Biodiesel emits fewer greenhouse gases and particulate matter, which can help to improve air quality and reduce the impact of transportation on the environment. In fact Biodiesel reduces greenhouse gas emissions by up to 86% compared to conventional diesel.

Additionally, biodiesel has a higher lubricity than petroleum diesel, which can help to reduce engine wear and extend the life of diesel engines. Finally, biodiesel can be made from a variety of feedstocks, including used cooking oil, which can help to reduce waste and support a circular economy. Biodiesel produces 6.9 units of energy for every 1 unit of fossil energy used in the production process.

| Advantage | Biodiesel | Conventional Diesel |

| Emissions | Lower emissions of greenhouse gases and particulate matter | Higher emissions of greenhouse gases and particulate matter |

| Biodegradability | Higher biodegradability | Lower biodegradability |

| Lubricity | Higher lubricity, reducing engine wear and tear | Lower lubricity, leading to increased engine wear |

| Feedstocks | Made from renewable feedstocks, including used cooking oil | Made from non-renewable fossil f |

How to make biodiesel from used cooking oil and Testing the Quality of Biodiesel

Biodiesel must meet certain quality standards to ensure it is safe to use in diesel engines and to maximize its performance. Quality standards are set by various organizations and can vary by country. In the United States, the ASTM International has established a set of specifications for biodiesel, known as ASTM D6751. This standard covers parameters such as flash point, viscosity, acid number, and sulfur content, among others.

Biodiesel Quality Standards

In addition to ASTM D6751, other quality standards may be used depending on the application of the biodiesel.For example, the European Union has established its own set of standards under the EN 14214 specification. These standards may include additional parameters such as cold filter plugging point and oxidation stability. The most common standard for biodiesel quality is the ASTM D6751 standard, which specifies a minimum cetane number of 47 and a maximum sulfur content of 15 ppm.

| Country | Biodiesel Quality Standard |

| USA | ASTM D6751 |

| European Union | EN 14214 |

| Brazil | ANP Resolution 45 |

| Australia | AS 3571 |

| Canada | CAN/CGSB-3.524 |

| India | IS 15607 |

Testing Methods to know how to make biodiesel from used cooking oil

To ensure the quality of biodiesel, various testing methods are used to measure its properties. These methods may include laboratory tests such as gas chromatography, infrared spectroscopy, and titration, among others. In addition, on-site testing methods such as the use of handheld devices to measure parameters like viscosity and acid number are also available. By regularly testing the quality of biodiesel, it is possible to ensure its performance and avoid potential engine damage.

Using Biodiesel in Vehicles and Machinery

Biodiesel is a renewable fuel source that has gained popularity in recent years due to its many benefits. However, before using biodiesel in vehicles and machinery, it is important to consider its compatibility with different types of engines.

Compatibility with Engines

Biodiesel can be used in most diesel engines with little to no modifications. However, it is important to check with the manufacturer of your engine to ensure that using biodiesel does not void your warranty. Biodiesel has a higher lubricity than conventional diesel, which can lead to longer engine life and reduced maintenance costs.

However, biodiesel may also cause fuel system leaks in older engines that have not been maintained properly. With using biofuels in cars, we can better know and answer this question how to make biodiesel from used cooking oil.

Conclusion

Cooking oil into diesel conversion is an eco-friendly and cost-effective way to produce a renewable fuel. For doing this we first need to answer this question, how to make biodiesel from used cooking oil?

In answer, by collecting and filtering the used cooking oil, and then performing a transesterification reaction using required chemicals and equipment, biodiesel can be produced. Testing the quality of biodiesel is important to ensure it meets the appropriate standards for use. Biodiesel reduces particulate matter emissions by up to 50% compared to conventional diesel.

Biodiesel is compatible with many engines, has environmental benefits and can be a solution to reduce dependence on fossil fuels. By following the step-by-step guide and taking necessary safety precautions, anyone can make biodiesel from used cooking oil and contribute to a more sustainable future.

FAQ

After find out about how to make biodiesel from used cooking oil, There are 3 frequently useful questions that they’re popular for readers.

What are the necessary chemicals and equipment required for making biodiesel from used cooking oil?

Methanol, sodium hydroxide, used cooking oil, glassware, and safety equipment.

Can any type of used cooking oil be used to make biodiesel?

Yes, most types of used cooking oil can be used, including vegetable oil, canola oil, and animal fats.

What are the safety precautions to take when convert cooking oil into diesel?

Wear safety equipment, work in a well-ventilated area, and avoid contact with the chemicals.

In Onliner.co, Our team with 12 professional members in each of content creation, on-page, off-page, and technical domain has always been able to achieve customer satisfaction with 12 years of experience in SEO. In the content creation sector, our expert writers are up to date and experienced to provide a high quality and unique contents.